Airtightness can be planned

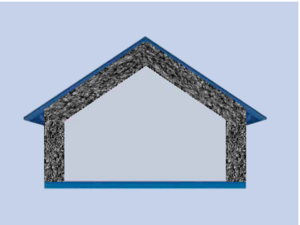

Solid construction

Shell made of concrete, brick and special insulation bricks. Installations possible in the wall without damaging the airtight layer. Suitable for walls and flat roofs, rather unusual for steep-pitched roofs. DIN 4108 part 3 is not applicable here.

Planning

It is not enough to instruct the skilled manual worker after the erection of roof structure, to install an airtight vapour check. Often almost unsolvable detail problems crop up then. How can a skilled manual worker be expected, for example, to properly seal a roof structure with countless collar beams, support frameworks, ridge gusset plates and struts?

The connections for material transitions

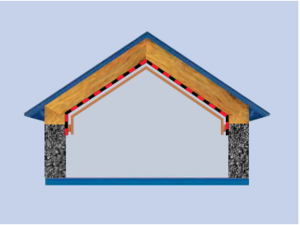

Eaves plate – jamb wall

The airtight layer is pulled down over the eaves plate, drawn to the solid jamb wall, and glued there to form airtight sealing. An additional mechanical fixing is essential, and this is normally done directly with the roof batten. The airtight layer must be glued to the interior plaster.

The penetrations

Outlet vents, ventilations, etc.

Pipe penetrations of any kind, even the smallest electrical pipes, must be sealed lastingly. The sealing materials must be resistant to ageing and flexible enough to withstand particularly large movements.

Doors, windows, etc.

Large openings such as doors and windows are often underestimated, but they are no different from penetrations in the building shell and are thus potential vulnerabilities. The airtight layer must be connected to the frame. The window strip Ampacoll FE with German registered design (DGM) is ideally suited for this application.

The installation level

Avoiding penetrations

The installation level should ensure that the technical installations can be arranged consistently on the warm side of the airtight layer and do not go through it. For larger installations such as sanitary or ventilation tubes, the installation level must be dimensioned as correspondingly large, and in extreme cases suspended ceilings are used.

Protection of the airtight layer

Besides serving as an installation level, the support system for the inner lining – in the simplest case, a framework – is particularly important for the protection of the airtight layer. The many panel brackets would otherwise make a sieve out of it, which would then probably have nothing in common with sealing.

Practical tips

Construction planner

- Work out an individual solution for airtightness and vapour tightness for the respective object.

- Think in terms of layers with entire building shell as a whole, in order to prevent conflicts at component transitions.

- Above all, consider the options available for construction of the building.

- Discuss the solution with the skilled manual worker.

- Consult the specialists – our technical consultants will be pleased to assist you.

Skilled manual worker

- Support the architect.

- Draw his attention to omissions (he cannot know everything, either).

- Introduce your own ideas, preferably at the time of planning.

- Discuss with the other skilled manual workers involved (workflow).

- Consult the specialists – our technical consultants will be pleased to help you.

Nice to know!

It will probably take many years before all stakeholders are following these principles as a matter of routine. Planners and those executing the work can support each other strongly, so that these innovations can be introduced quickly and smoothly.

Nice to know!

Only through the intensive cooperation of all planners, skilled manual workers and material suppliers involved can we create safe and durable buildings. The company Ampack has developed a variety of solutions for the anticipated problems associated with execution. You stand to benefit from our groundwork.