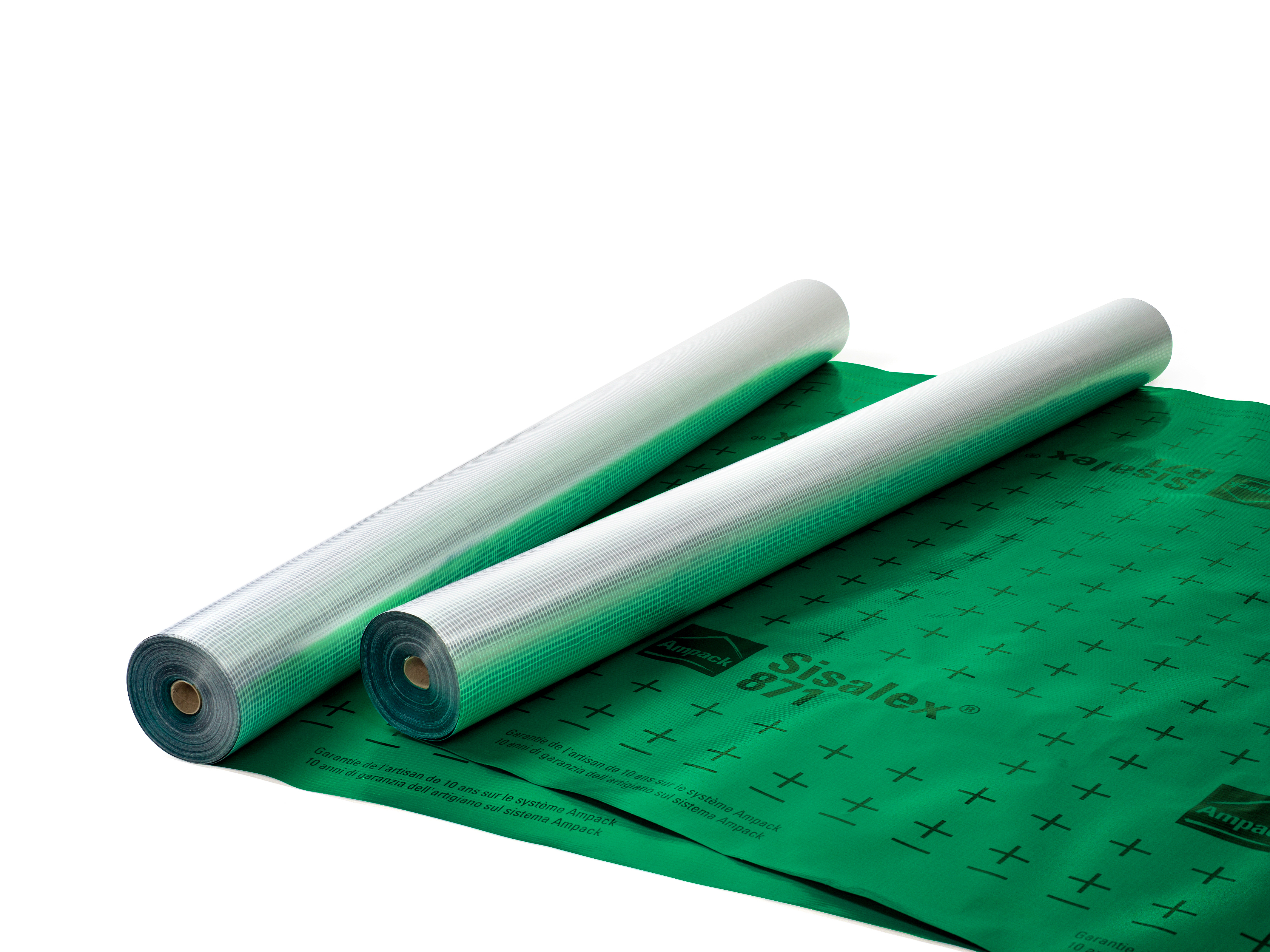

Sisalex 871

Radon barrier

Four layer radon barrier.

- Protection against radon gas, methane and humidity

- Extremely stable and tear-resistant

- Alkali-resistant

Four layer radon barrier consisting of two layers of PE film, a polyester fibre inlay and a 0,008 mm thick aluminium layer.

Conditions for the twenty-year premium warranty include registering the building object and the Ampack products used. In addition, our products must be used as part of a system. For further details, please see our General Warranty Conditions.

| Article number | Description | Roll dimensions |

|---|---|---|

7640115531001 | Sisalex 871 | 2,0 m × 50 m = 100 m2 |

| Property | Value | Standard |

|---|---|---|

|

Thickness |

0,4 mm | EN 1849-2 |

|

Mass per unit area |

350 g/m2 |

EN 1849-2 |

|

Water vapour permeability, sD value |

> 1'500 m | EN 1931 |

|

Width of overlap |

15 cm | |

|

Methane permeability |

4,3 x 10-14 kg m/s |

|

|

Radon permeability |

1,4 x 10-13 m²/s |

|

| Visible defects | none | |

| Values after artificial ageing | ||

Technical data sheets

|

|

Technical data sheet: Sisalex 871 | Technical data sheet: Sisalex 871, radon barrier |

Tendering texts

|

|

Tendering text: Sisalex 871 | Tendering text: Sisalex 871, radon barrier |

Test reports

|

|

Test report: Sisalex 871 and overlaps | Test report: Sisalex 871, radon barrier and overlaps |

|

|

Test report: Sisalex 871 sleeves | Test report: Sisalex 871, radon barrier and Ampacoll Radon, sleeves |

Product photos

|

|

Product photo: Sisalex 871 | Product photo: Sisalex 871, radon barrier |

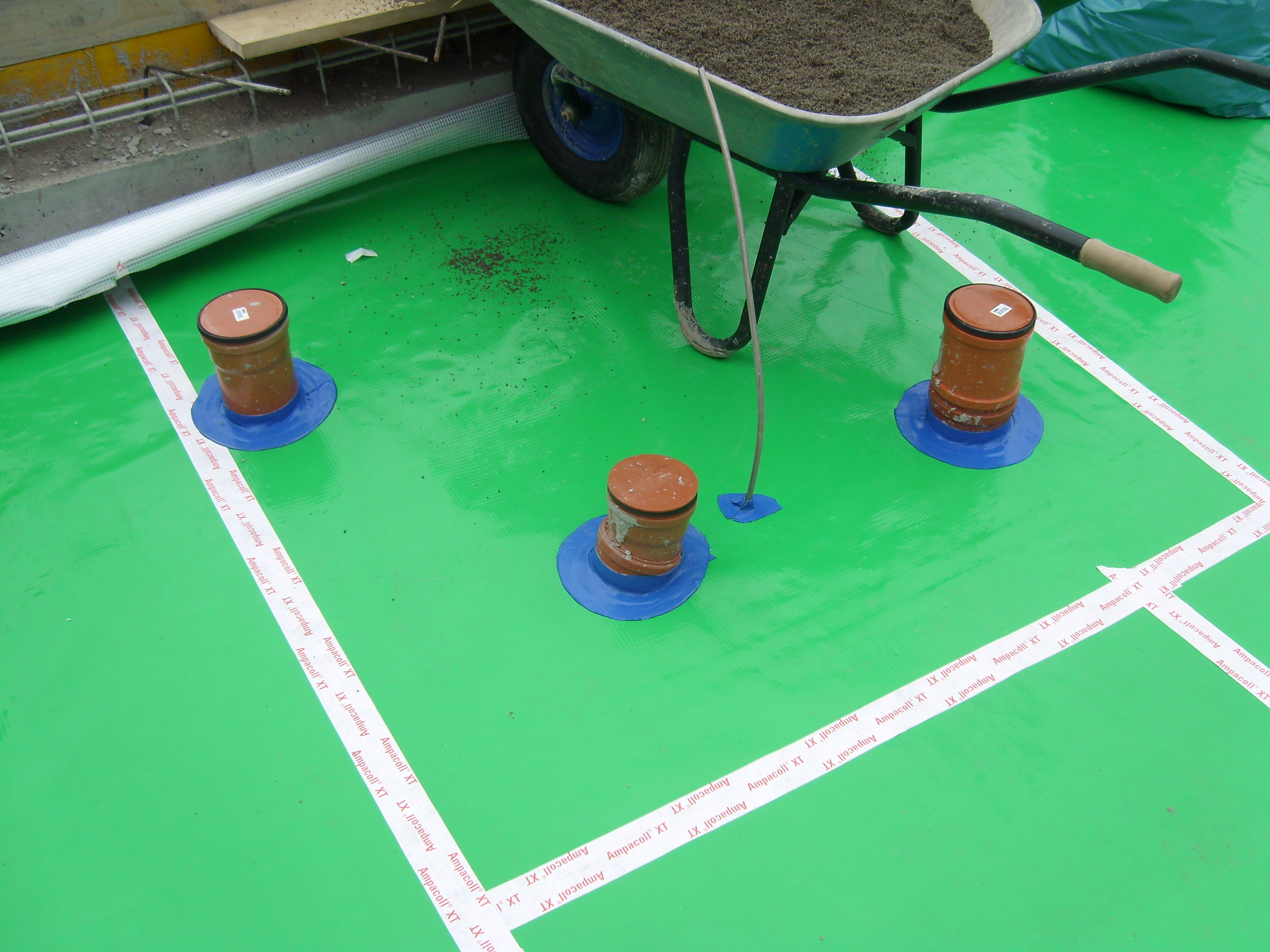

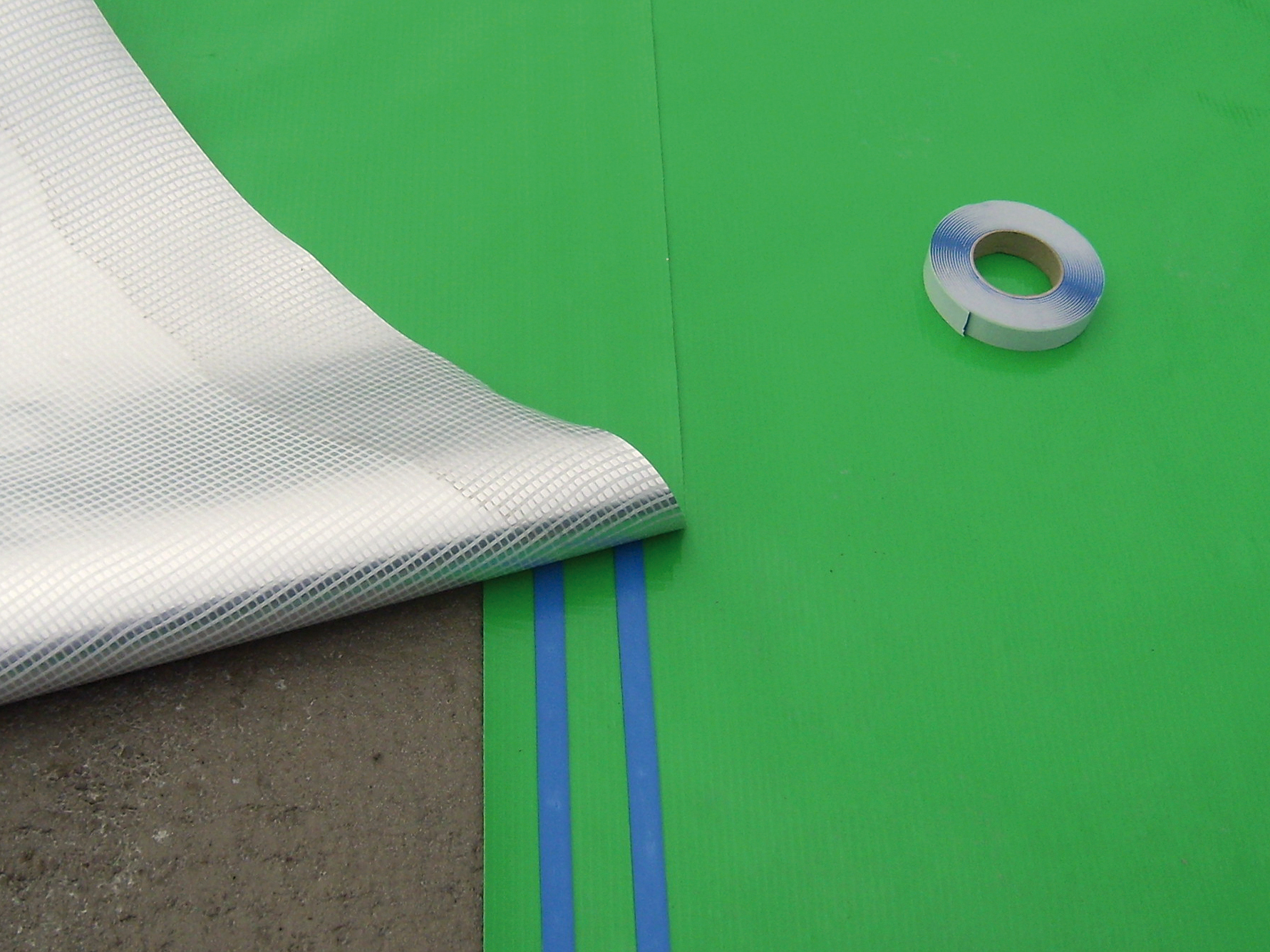

Application photos

|

|

Application photo: Sisalex 871 | Application photo: Sisalex 871, radon barrier |

|

|

Application photo: Sisalex 871 | Application photo: Sisalex 871, radon barrier |

|

|

Application photo: Sisalex 871 | Application photo: Sisalex 871, radon barrier |

The gas barrier is used to prevent gaseous emissions that occur naturally in the soil (radon gas, methane, carbon dioxide and other harmful gases) or existing environmental pollution (landfill) in contaminated soil penetrating from the foundation or basement ceiling of the building into the living area, thereby protecting the occupants.

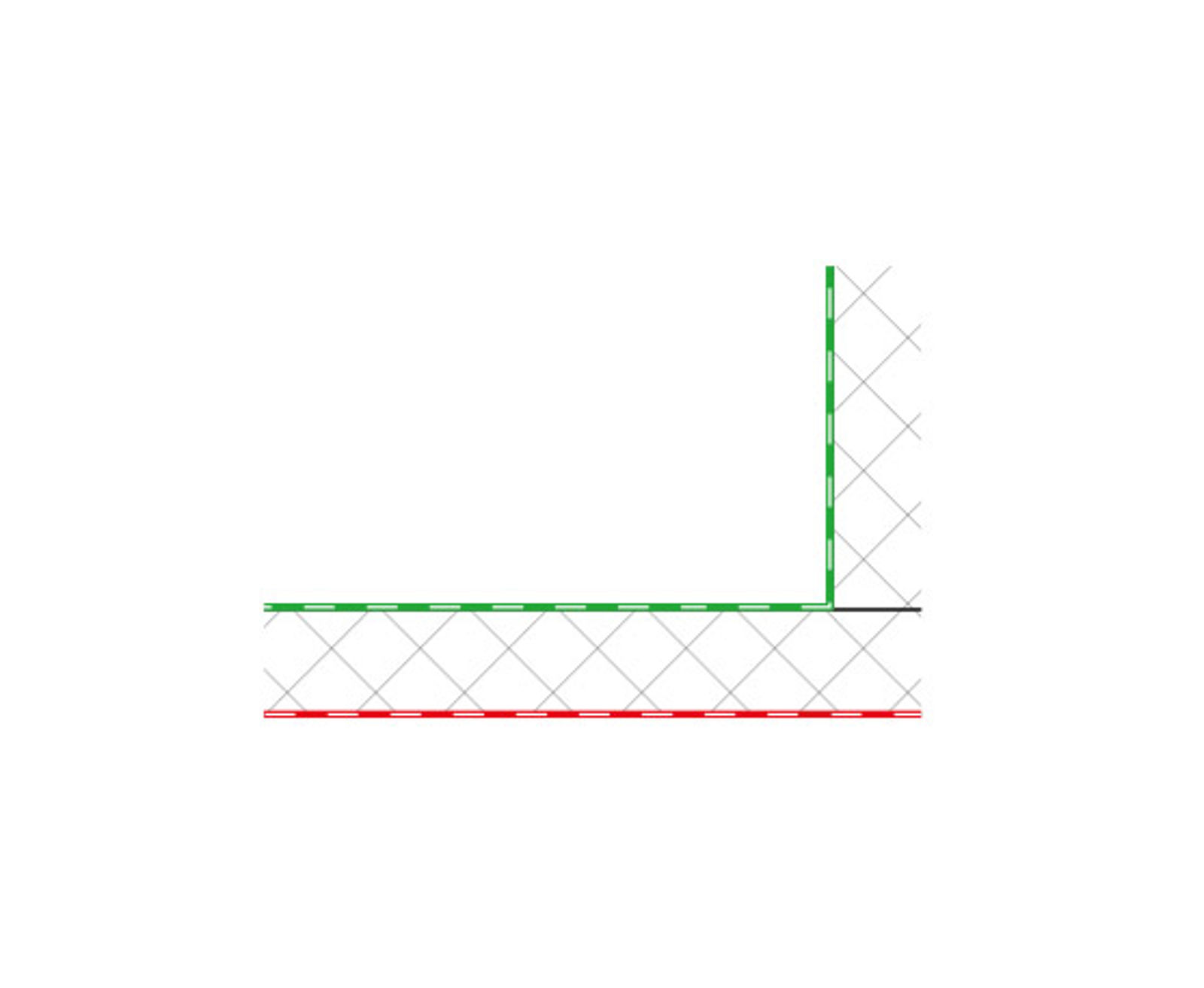

Installation instructions

Plane laying:

- on clean layer (fine grade, lean concrete bed) between strip foundations

- on clean layer below the floor slab (clean layer at least 5 cm)

- directly onto the floor slab

- within the structure of the basement ceiling (concrete, Hourdis ceilings, beamed ceiling)

Lay the dark green side (weathering side) facing up, and the PE or aluminium side against the surface. The joints should

overlap by 15 cm and must be kept dry and free of dust and dirt for gluing. The same rules apply to the gas-tight laying of a

vapour barrier: double-sided butyl tape for butt joints (sealing function) and application of acryl adhesive tape across the top (mechanical fixation). Edges at walls, pillars and penetrations should be 15 cm high and must to be sealed. Surfaces must be cleaned and any sharp, pointed areas and objects or any mortar remnants are to be removed in advance. Holes and offsets in the surface must be levelled out. The vapour barrier must be protected immediately after installation by applying the additional structural layers (concrete slab, insulation, underlay). When installing these layers, pay particular attention to ensuring that the vapour barrier is not stretched or shifted, and that no tears occur in the area of penetration. All tears are to be sealed. Double adhesion (sealing function and additional mechanical fixation) is necessary in order to achieve a gas-tight seal.