Ampatex Sinco

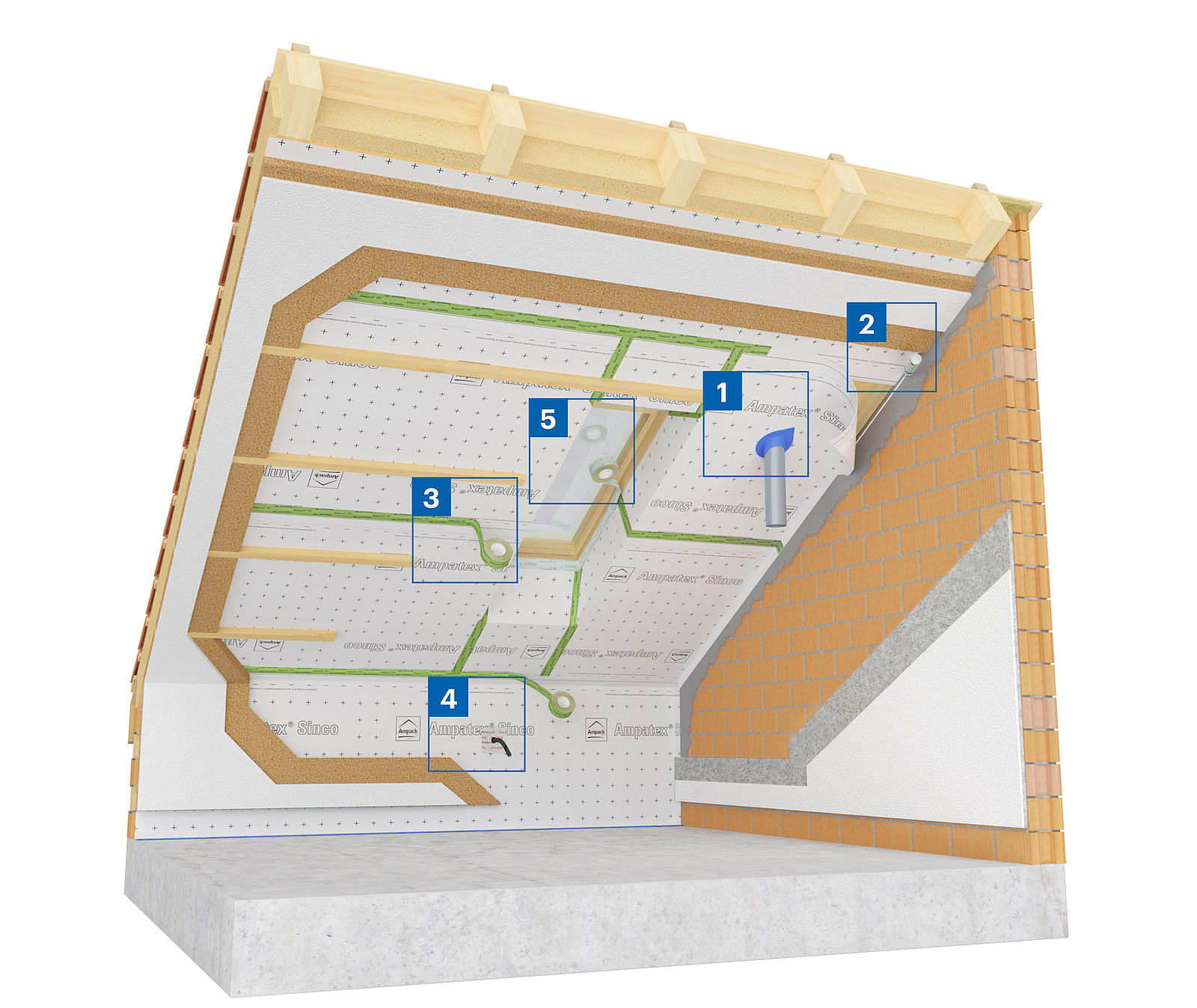

Vapour check and airtight layer

Vapour check and airtight layer. Also suitable for cellulose insulation.

- Does not stretch or shrink

- Cutting and orientation aid

- Does not attract dust

- Translucent – for security when blowing out with cellulose fibres

Double layer, tear-resistant vapour check and airtight layer made of thermoset PP fibres with copolymer fill layer. Also suitable for cellulose insulation.

Einsatzbereich

The safe alternative to all polythene films.

Conditions for the twenty-year premium warranty include registering the building object and the Ampack products used. In addition, our products must be used as part of a system. For further details, please see our General Warranty Conditions.

| Article number | Description | Roll dimensions |

|---|---|---|

7640115536679 | Ampatex Sinco | 1,5 m × 100 m = 150 m2 |

7640115536969 | Ampatex Sinco | 3,0 m × 50 m = 150 m2 |

| Property | Value | Standard |

|---|---|---|

| Harmonised European Standard | EN 13984:2013 | |

| Product description | Typ A | EN 13984:2013 |

|

Mass per unit area |

100 g/m2 |

EN 1849-2 |

|

Straightness |

< 75 mm/10 m |

EN 1848-2 |

|

Fire behaviour |

E | EN 13 501-1 / EN ISO 11925-2 |

| Waterproofing | approved at 2 kPa | EN 1928, procedure A |

|

Water vapour permeability, sD value |

5 m | EN 1931 |

|

Width of overlap |

10 cm | |

|

Temperature resistance |

– 40 to +80 °C | |

|

Shear resistance of the joints |

151 N | EN 12 317-2 |

|

Maximum tensile strength longitudinal / transverse |

160 / 160 N/5 cm |

EN 12 311-2, without support liner EN 13 859-1, Appendix A, with support liner |

|

Elongation longitudinal / transverse |

30 % / 30 % |

EN 12 311-2, without support liner EN 13 859-1, Appendix A, with support liner |

|

Resistance to tearing (nail) longitudinal / transverse |

200 / 200 N |

EN 12 310-1 without support liner EN 13 859-1, Appendix B, with support liner |

| Air tightness | air tight | |

| Visible defects | none | EN 1850-2 |

| Values after artificial ageing | ||

|

Water vapour permeability, sD value |

approved | EN 1296, 70°C / EN 1931 |

Technical data sheets

|

|

Technical data sheet: Ampatex Sinco | Technical data sheet: Ampatex Sinco, vapour check and airtight layer |

Declarations of performance

|

|

Declaration of performance: Ampatex Sinco | Declaration of performance: Ampatex Sinco 1.5 x 100 m, vapour check and airtight layer |

|

|

Declaration of performance: Ampatex Sinco | Declaration of performance: Ampatex Sinco 3.0 x 50 m, vapour check and airtight layer |

Product inserts

|

|

Product insert: Ampatex Sinco | Product insert: Ampatex Sinco 1.5 x 100 m, vapour check and airtight layer |

|

|

Product insert: Ampatex Sinco | Product insert: Ampatex Sinco 3.0 x 50 m, vapour check and airtight layer |

Tendering texts

|

|

Tendering text: Ampatex Sinco | Tendering text: Ampatex Sinco, vapour check and airtight layer |

Product photos

|

|

Product photo: Ampatex Sinco | Product photo: Ampatex Sinco, vapour check and airtight layer |

Ampatex Sinco is both a vapour check and an airtight layer. All joints, gaps, overlaps, connections and openings must be hermetically sealed. Surface damage must be sealed. In dry interiors, Ampatex Sinco should be used on the warm side of the heat-insulating layer, and in areas where there is an overlap it should be fastened with concealed staples or nails. The smooth, printed side faces into the room and this is the surface onto which the next product should be taped. When laying, make sure that the strips overlap by 10 cm. The overlaps should then be completely covered with the Ampacoll INT supplied. Ampacoll DT adhesive tape is useful where the underlying material cannot be nailed. Finally the lining on the inside is fixed in place. Ampacoll BK 530 or Ampacoll RA are used for edge connections. Porous or dusty surfaces should be pretreated with Ampacoll Primax. Penetrations such as ventilation pipes, conduits, purlins, rafters, etc. should be permanently sealed with Ampacoll BK 535, 50 mm wide. With porous, dusty or rough surfaces, a pretreatment of Ampacoll Primax is also

required.

|

|

Dampfbremsen im winterlichen Rohbau | Einbau von Dampfbremsen im winterlichen Rohbau |

|

|

Luftdichtheitsbahnen bei Einblasdämmungen | Verlegung von Luftdichtheitsbahnen bei Einblasdämmungen |