Ampatop A silver plus

Neu

Non-combustible, diffusion-permeable reflective membrane and electrical smog barrier for roofs and façades

Non-combustible, diffusion-permeable reflective membrane.

- Fire behaviour: A2-s1, d0

- Non-combustible: no contribution to fire in the ventilation level (curtain wall)

- Extremely high tensile strength: fallresistant in accordance with DIN 4426

- UV-stable

- For open façades with joint widths of up to 50 mm / 50%

- Surface made of micro-perforated aluminium foil: diffusion-permeable, reflects heat and electromagnetic radiation

- Particularly suitable for ventilated façades on multi-storey buildings and behind energy-generating systems

Non-combustible, diffusion-permeable reflective membrane for ventilated, closed façades or façades with open joints behind energy-generating systems (PV, solar), and as a fall-resistant roofing membrane.

| Item no. | Product name | Roll size |

|---|---|---|

| 7640442092121 | Ampatop A silver plus with integrated tape | 1,2 m × 35 m = 42 m2 |

| Property | Value | Standard |

|---|---|---|

| Harmonised European Standard | EN 13859-1:2014, EN 13859-2:2014 | |

|

Mass per unit area |

430 g / m2 |

EN 1849-2 |

|

Straightness |

< 75 mm / 10 m |

EN 1848-2 |

|

Fire behaviour |

A2-s1, d0 (CH: RF 1) | EN 13 501-1 / EN ISO 11925-2 |

|

Resistance to water penetration |

W1 | EN 1928, procedure A |

|

Water vapour permeability, sD value |

0,08 m | EN 1931 |

|

Width of overlap |

10 cm | |

|

Temperature resistance |

– 35°C – + 90°C | |

|

Maximum tensile strength longitudinal / transverse |

3000 / 3200 N / 5 cm |

|

|

Elongation longitudinal / transverse |

6 / 5 % |

|

|

Resistance to tearing (nail) longitudinal / transverse |

580 / 450 N |

EN 12 310-1 without support liner EN 13 859-1, Appendix B, with support liner |

|

Dimensional Stability |

2 % |

EN 1107-2 |

|

Cold bending behaviour (flexibility) |

-35 °C | EN 1109 |

|

Emissivity |

5 % |

|

|

Reflexivity |

95 % |

|

| approved | Driving rain test TU Berlin | |

|

Outdoor weathering |

9 months | |

|

Gap width up to |

50 mm / 50 % | |

| 5'000-hour test | approved | |

|

Minimum roof slope |

10° | |

| Geeignet als Behelfsdeckung | yes | |

| Visible defects | none | |

| Values after artificial ageing | ||

Technical data sheets

|

|

Technical data sheet: Ampatop A silver plus | Technical data sheet: Ampatop A silver plus, non-combustible, diffusion-permeable reflective membrane and electrical smog barrier for roofs and façades |

Advertising media

|

|

Folder: Non-combustible assortment | Folder: Non-combustible assortment |

Product inserts

|

|

Product insert: Ampatop A silver plus | Product insert: Ampatop A silver plus, non-combustible, diffusion-permeable reflective membrane and electrical smog barrier for roofs and façades |

Product photos

|

|

Product photo: Ampatop A silver plus | Product photo: Ampatop A silver plus, non-combustible, diffusion-permeable reflective membrane and electrical smog barrier for roofs and façades |

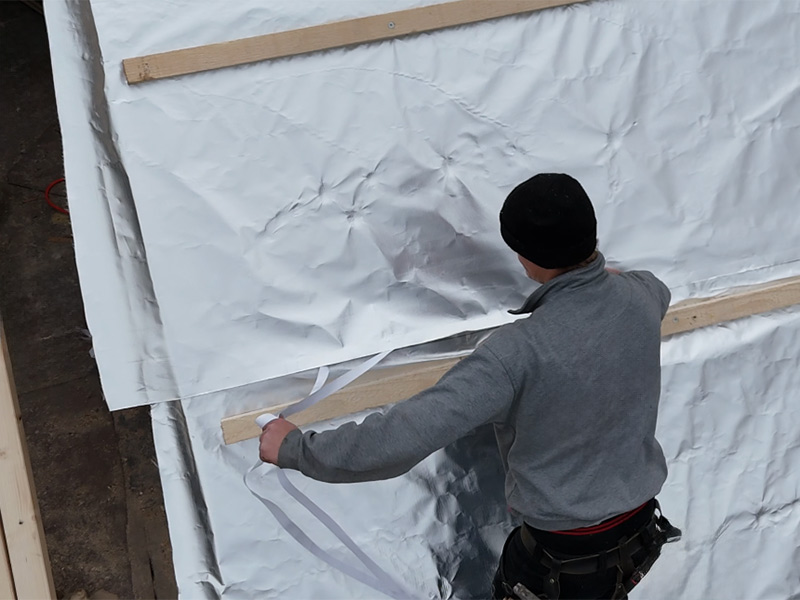

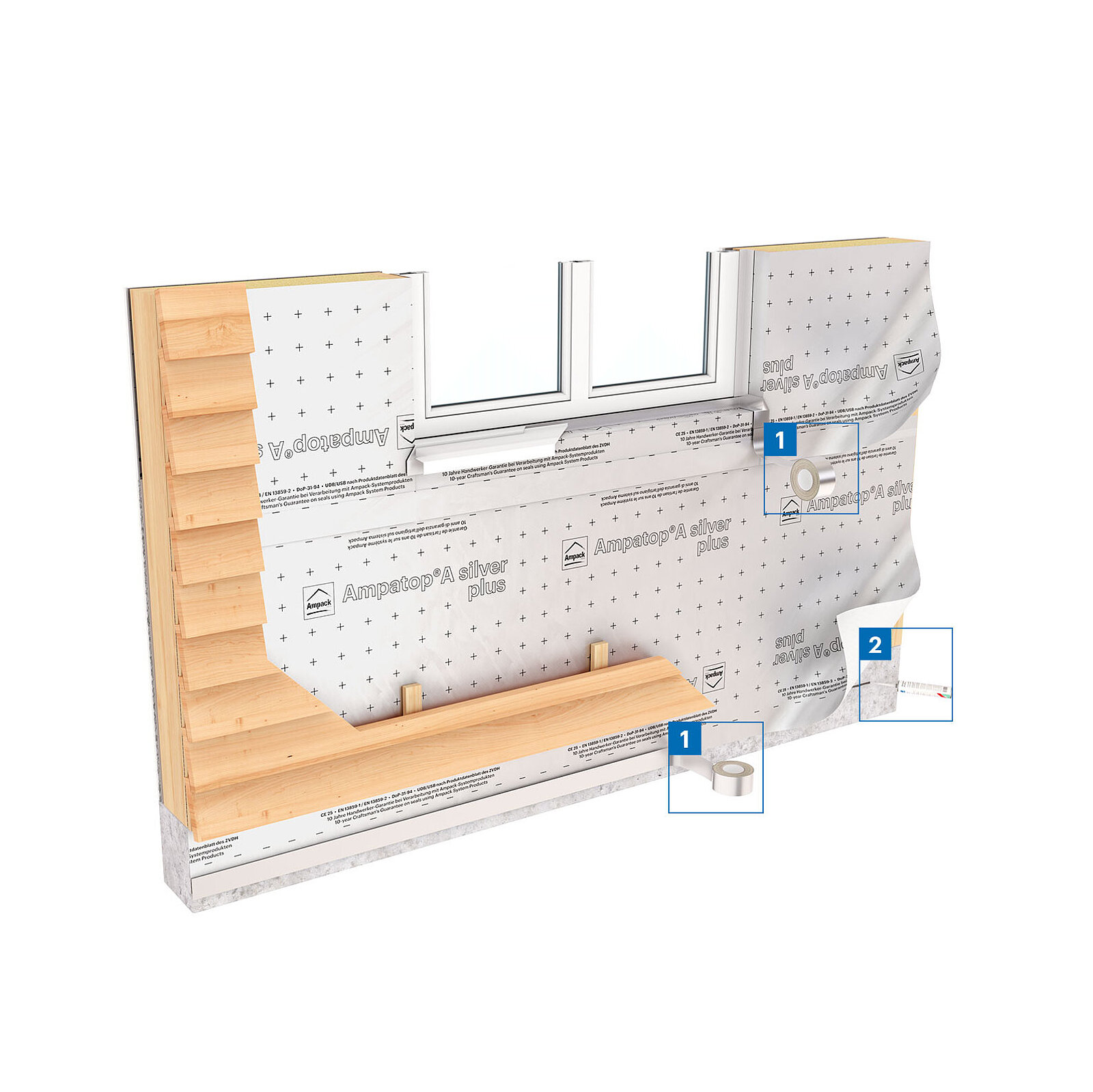

Application photos

|

|

Application photo: Ampatop A silver plus | Application photo: Ampatop A silver plus, non-combustible, diffusion-permeable reflective membrane and electrical smog barrier for roofs and façades |

|

|

Application photo: Ampatop A silver plus | Application photo: Ampatop A silver plus, non-combustible, diffusion-permeable reflective membrane and electrical smog barrier for roofs and façades |

|

|

Application photo: Ampatop A silver plus | Application photo: Ampatop A silver plus, non-combustible, diffusion-permeable reflective membrane and electrical smog barrier for roofs and façades |

Ampatop A silver plus can be installed either horizontally or vertically, with the silver side facing outwards. Roll out the membrane, line it up, cut it to length, pull it tight and fix it in place (e. g. using stainless steel tacks). This takes place invisibly within the overlap, which must be at least 10 cm wide. Overlaps must be bonded in a rainproof and windtight manner using the integrated tapes or the system adhesive tape Ampacoll A Tape silver. Rub down adhered areas thoroughly. Cross joints must also overlap by 10 cm and be bonded with Ampacoll A Tape silver.

Always mount the final mechanical fixation after laying (e.g. counter battens)! Ampacoll ND Pads (nail seals) or Ampacoll ND.Band (nail sealing tape) should be used for this. Ampacoll Profix liquid adhesive can be used for connections. These must then be covered with the membrane or the adhesive tape Ampacoll A Tape silver. This best-practice method also applies to necessary penetrations (e. g. for air vents, balcony mounts and cable holes) as well as window joints. Visible leakage of the adhesive must be avoided.

Ampacoll Profix is also used to bond Ampatop A silver plus to metal furring within the insulation layer. The maximum distance horizontally or vertically is 1,20 m, and the minimum width of the profiles is 4 cm. The insulation must fill the entire cavity and be laid evenly and secured in place, so that the façade membrane is not negatively affected (no bulging, pushing out, etc.). When installing on surfaces that cannot be stapled, pressure-resistant insulating materials or similar, it is recommended to bond using Ampacoll Profix every 60 cm horizontally and vertically, especially when only individual or sporadic brackets are installed for final fixing. The maximum distance between individual attachments is 60 cm (horizontal and vertical).

Attention: Protruding attachments must be split at insulation level and should not penetrate the membrane (e.g. two-piece brackets with clamping flanges).

Attention: Never allow the membrane to come into contact with fresh mortar, cement or other alkaline products. This may damage the aluminium layer.

Tip: The aluminium surface reflects heat and light. Appropriate eye protection or sun protection must therefore be worn during installation, especially in sunny conditions.