Avoiding the risk of condensation

Prevention of condensed water

A suitably dimensioned thermal insulation ensures that the inner surface temperature is above the dew point temperature ϑT relevant for the room climate.

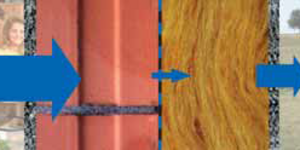

Prevention of condensation inside the construction

The diffusion resistance of different materials in a multilayer construction must generally reduce from the warm side to the cold side in each layer.

Vapour checks and vapour seals

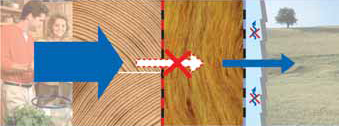

Rule 1

For a construction with existing ventilation or a diffusion-permeable external layer (e.g. timber formwork)

- Vapour check with a low sd-value im Bereich von 5 bis 20 m

Merke: Innen so diffusionsdicht wie nötig, aussen so diffusionsoffen wie möglich

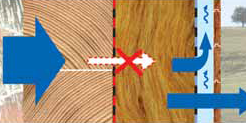

Potential problems with vapour checks and vapour seals

The vapour check or seal is not handled cleanly:

- Joints are poorly glued or not at all.

- Edge connections are badly designed or "forgotten".

- Penetrations are not sealed.

- Damage to the surface is not repaired.

- Unsuitable, cheap adhesive strips which come off after a short time.

The ventilation installed at the time of construction becomes inoperable due to incorrect design:

- Too small or even no local inlet/foul air holes at the eaves and ridge.

- No air openings with large penetrations such as roof windows, chimneys, etc.

- In the case of a ventilated flat roof, insulation pressed into the underroof.

The trapped moisture is not taken into account:

- After installation of the wet layers (underlays, plaster, etc.), the windows are not opened or the rooms are insufficiently ventilated.

- Insufficient drying times, construction too tightly scheduled.

- Inclusion of components with too high a level of moisture (wet wooden beams, etc.)

Planning mistakes

- The planner provides for a vapour check, although a vapour seal would be required for the construction concerned, or forgets it completely.

- The planner leaves the choice of the vapour check to the skilled manual worker without elucidating the further build-up of layers and other major significant factors.

- The planner fails to verify the correct installation of thermal insulation and vapour check, as well as the functionality of the ventilation.