Ampatex LDA 0.02 plus

Vapour check for renovation

Vapour check for renovation

- Integrated tape on both side

- Saves time during installation

- Cutting and orientation aid

- Does not tear or snag on nails

Highly permeable airtight three-layer membrane for roof renovation over the support structure. This membrane is highly permeable (sd value 0,025 m) yet airtight (a value: 0,004).

Einsatzbereich

External airtight layer for roof renovations from the outside without removal of existing insulation.

Conditions for the twenty-year premium warranty include registering the building object and the Ampack products used. In addition, our products must be used as part of a system. For further details, please see our General Warranty Conditions.

| Article number | Description | Roll dimensions |

|---|---|---|

| 7640115535603 | Ampatex LDA 0.02 plus integrated tapes on both sides | 1,5 m × 50 m = 75 m2 |

| Property | Value | Standard |

|---|---|---|

| Harmonised European Standard | EN 13984:2013 | |

| Product description | Typ A | EN 13984:2013 |

|

Mass per unit area |

175 g/m2 |

EN 1849-2 |

|

Straightness |

< 75 mm / 10 m |

EN 1848-2 |

|

Fire behaviour |

E | EN 13 501-1 / EN ISO 11925-2 |

|

Resistance to water penetration |

W1 | EN 1928 |

|

Water vapour permeability, sD value |

0,02 m | EN 1931 |

|

Width of overlap |

10 cm | |

|

Temperature resistance |

-40 to +80 °C | |

|

Maximum tensile strength longitudinal / transverse |

350 / 300 N / 5 cm |

EN 12 311-2, without support liner EN 13 859-1, Appendix A, with support liner |

|

Elongation longitudinal / transverse |

75 / 50 % |

EN 12 311-2, without support liner EN 13 859-1, Appendix A, with support liner |

|

Resistance to tearing (nail) longitudinal / transverse |

260 / 290 N |

EN 12 310-1 without support liner EN 13 859-1, Appendix B, with support liner |

|

Cold bending behaviour (flexibility) |

-40 °C | EN 1109 |

|

Resistance to air penetration (a value) |

< 0,004 m3/m2 x h x 50 Pa |

EN 13859-2, point 4.3.4 / EN 12114 |

| Air tightness | air tight | |

|

Outdoor weathering |

2 weeks (with mechanical fixing) | |

| Visible defects | none | EN 1850-2 |

| Values after artificial ageing | ||

|

Maximum tensile strength longitudinal / transverse |

280 / 240 N/5 cm |

EN 13859-1, appendix C, EN 1297, EN 1296 |

|

Elongation longitudinal / transverse |

280 / 240 N/5 cm |

EN 13859-1, appendix C, EN 1297, EN 1296 |

|

Resistance to water penetration |

W1 | EN 13859-1, appendix C, EN 1297, EN 1296 |

Technical data sheets

|

|

Technical data sheet: Ampatex LDA 0.02 plus | Technical data sheet: Ampatex LDA 0.02 plus, vapour check for renovation |

Declarations of performance

|

|

Declaration of performance: Ampatex LDA 0.02 plus | Declaration of performance: Ampatex LDA 0.02 plus 1.5 x 50 m, vapour check for renovation |

Product inserts

|

|

Product insert: Ampatex LDA 0.02 plus | Product insert: Ampatex LDA 0.02 plus 1.5 x 50 m, vapour check for renovation |

Tendering texts

|

|

Tendering text: Ampatex LDA 0.02 plus | Tendering text: Ampatex LDA 0.02 plus, vapour check for renovation |

Product photos

|

|

Product photo: Ampatex LDA 0.02 plus | Product photo: Ampatex LDA 0.02 plus, vapour check for renovation |

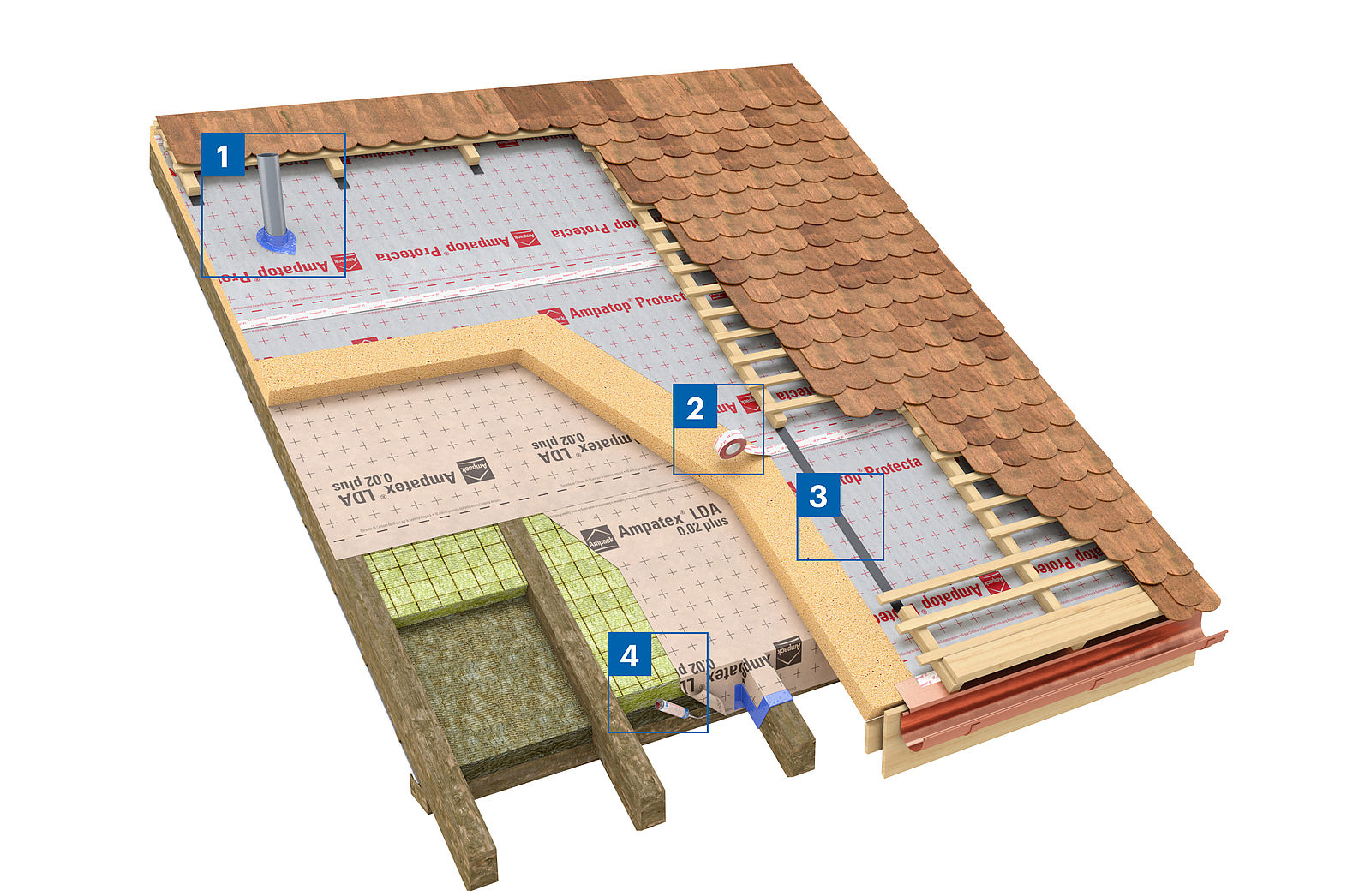

Ampatex LDA 0.02 plus is used as the airtight layer in the restoration of the roof while retaining the insulation between the rafters, when the inside space covering is not airtight. First, the rafters must be fully insulated. Under no circumstances should there be any open cavity between the insulation and top edge of the rafter. Ampatex LDA 0.02 plus is then laid parallel to the eaves and with the printed side facing the moulder on to the existing support structure, formwork or cavity insulation with 10 cm overlap and then nailed (Breitkopf brand nails) or stapled to cover the overlapping area. Bond the overlaps with integrated tape so that they are airtight. Rub the bonding surface thoroughly. Also overlap butt joints by 10 cm and bond with Ampacoll Superfix or Ampacoll XT 60 mm. Joints to inflow sheets and flanging on fireplaces, skylights and other fixtures etc. must be permanently bonded with Ampacoll Superfix and fixed mechanically where

necessary. Penetrations such as ventilation towers, outlet vents, etc. should be sealed with Ampacoll BK 535 butyl rubber tape. Porous, dusty and non-woven substrates must be pre-treated with Ampacoll Primax or Airmax when using Ampacoll BK butyl tapes. Special attention should be paid to the joints of the air-sealing sheet at the eaves and gable end.

The sheet must be attached to the underlying components so that it is airtight. The over-insulation should be installed

immediately after laying the Ampatex LDA 0.02 plus in order to avoid condensation. The following rule of thumb can be applied for the thickness of the over-insulation: it should be about 1∕3 of total insulation thickness. Please note the country-specific heat engineering standards and specifica-tions of the insulation manufacturers.