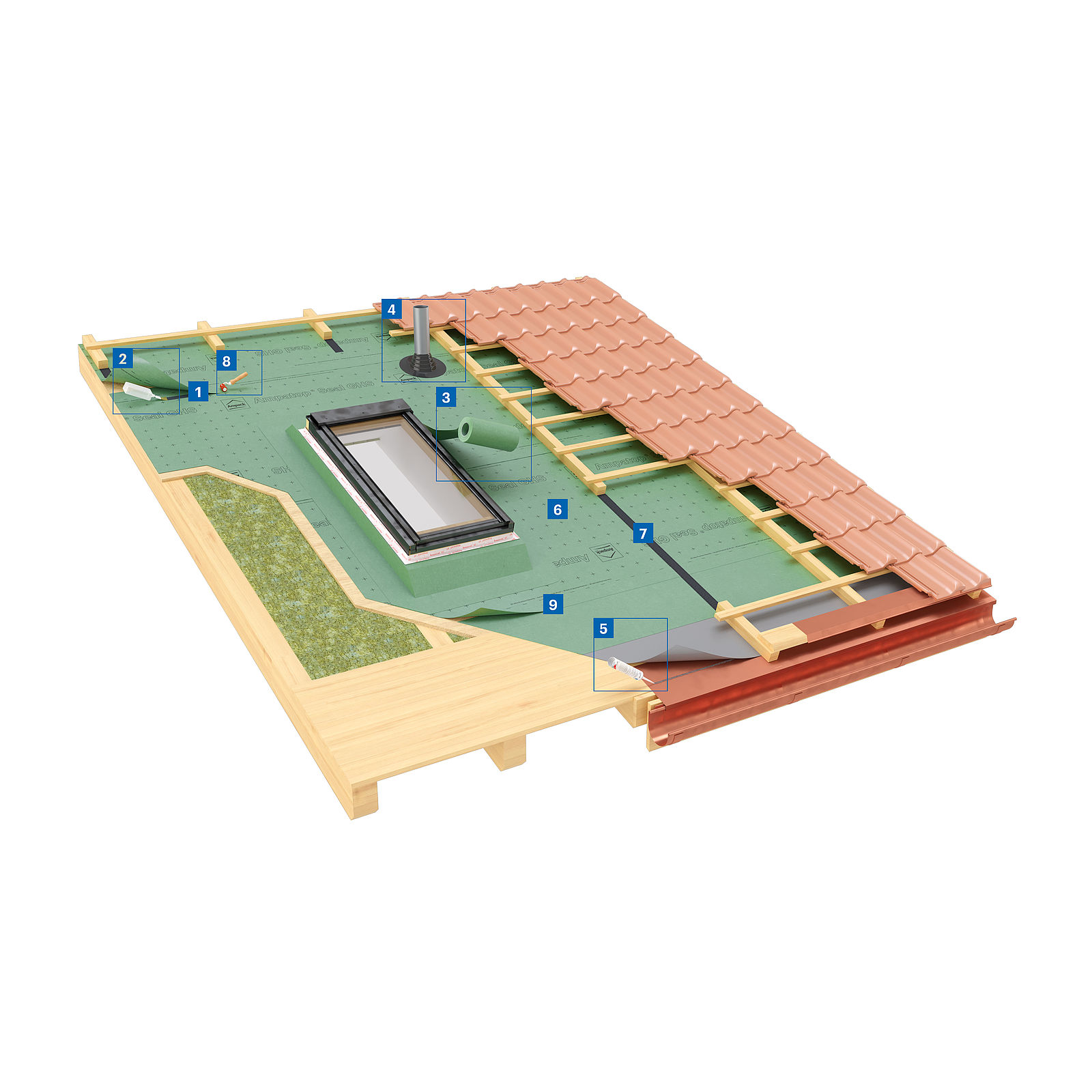

Ampatop Seal GHS

Weldable roof membrane

Triple layer weldable roof membrane.

- Weldable with solvent bonding and heat

- Both sides are processed, no waste

- Cutting and orientation aid

- Monolithic TPU technology

- For low roof pitches

- Hail resistant

- Abrasion resistant

- Suitable for rooftop PV systems

Triple layer weldable roof membrane. Overlaps and connections are welded seamlessly and homogenously. The membrane consists of a fleece and an upper and lower layer of TPU. Monolithic TPU technology.

Conditions for the twenty-year premium warranty include registering the building object and the Ampack products used. In addition, our products must be used as part of a system. For further details, please see our General Warranty Conditions.

| Article number | Description | Roll dimensions |

|---|---|---|

| 7640442090677 | Ampatop Seal GHS | 1,5 m × 30 m = 45 m2 |

| 7640442090714 | Ampatop Seal GHS Jumbo | 1,5 m × 400 m = 600 m2 |

| 7640442090691 | Ampatop Seal GHS | 3,0 m × 20 m = 60 m2 |

| 7640442090738 | Ampatop Seal GHS Jumbo | 3,0 m × 400 m = 1’200 m2 |

| Property | Value | Standard |

|---|---|---|

| Harmonised European Standard | EN 13859-1:2014 | |

|

Mass per unit area |

350 g/m2 |

EN 1849-2 |

|

Straightness |

< 30 mm/10 m |

EN 1848-2 |

|

Fire behaviour |

E | EN 13 501-1 / EN ISO 11925-2 |

|

Brandkennziffer |

4.2 | VKF |

|

Resistance to water penetration |

W1+ | EN 1928 |

|

Water vapour permeability, sD value |

0,20 m | EN 1931 |

|

Width of overlap |

10 cm | |

|

Temperature resistance |

-40 to +100 °C | |

|

Maximum tensile strength longitudinal / transverse |

350 / 380 N/5 cm |

EN 12 311-2, without support liner EN 13 859-1, Appendix A, with support liner |

|

Elongation longitudinal / transverse |

50 / 70 % |

EN 12 311-2, without support liner EN 13 859-1, Appendix A, with support liner |

|

Resistance to tearing (nail) longitudinal / transverse |

250 / 240 N |

EN 12 310-1 without support liner EN 13 859-1, Appendix B, with support liner |

|

Dimensional Stability |

-2 % |

EN 1107-2 |

|

Cold bending behaviour (flexibility) |

-20 °C | EN 1109 |

| approved | Driving rain test TU Berlin | |

|

Outdoor weathering |

6 months | |

| 5'000-hour test | approved | |

|

Minimum roof slope |

3° | |

| Visible defects | none | |

| Values after artificial ageing | ||

|

Maximum tensile strength longitudinal / transverse |

350 / 380 N/5 cm |

EN 13859-1, appendix C, EN 1297, EN 1296 |

|

Elongation longitudinal / transverse |

350 / 380 N/5 cm |

EN 13859-1, appendix C, EN 1297, EN 1296 |

|

Resistance to water penetration |

W1+ | EN 13859-1, appendix C, EN 1297, EN 1296 |

Technical data sheets

|

|

Technical data sheet: Ampatop Seal GHS | Technical data sheet: Ampatop Seal GHS, weldable roof membrane |

Advertising media

|

|

Folder: Ampatop Seal (GHS) | Folder: Ampatop Seal (GHS), weldable roof membrane |

Declarations of performance

|

|

Declaration of perfomance: Ampatop Seal GHS | Declaration of perfomance: Ampatop Seal GHS 1,5 x 400m, weldable roof membrane |

Tendering texts

|

|

Tendering text: Ampatop Seal GHS | Tendering text: Ampatop Seal GHS, weldable roof membrane |

Product inserts

|

|

Product insert: Ampatop Seal GHS | Product insert: Ampatop Seal GHS 1,5 x 30 m, weldable roof membrane |

|

|

Product insert: Ampatop Seal GHS | Product insert: Ampatop Seal GHS 1,5 x 400 m, weldable roof membrane |

|

|

Product insert: Ampatop Seal GHS | Product insert: Ampatop Seal GHS 3,0 x 20 m, weldable roof membrane |

|

|

Product insert: Ampatop Seal GHS | Product insert: Ampatop Seal GHS 3,0 x 400 m, weldable roof membrane |

Processing tips

|

|

Laying instructions: Ampatop Seal (GHS) | Laying instructions: Ampatop Seal (GHS), weldable roof membrane |

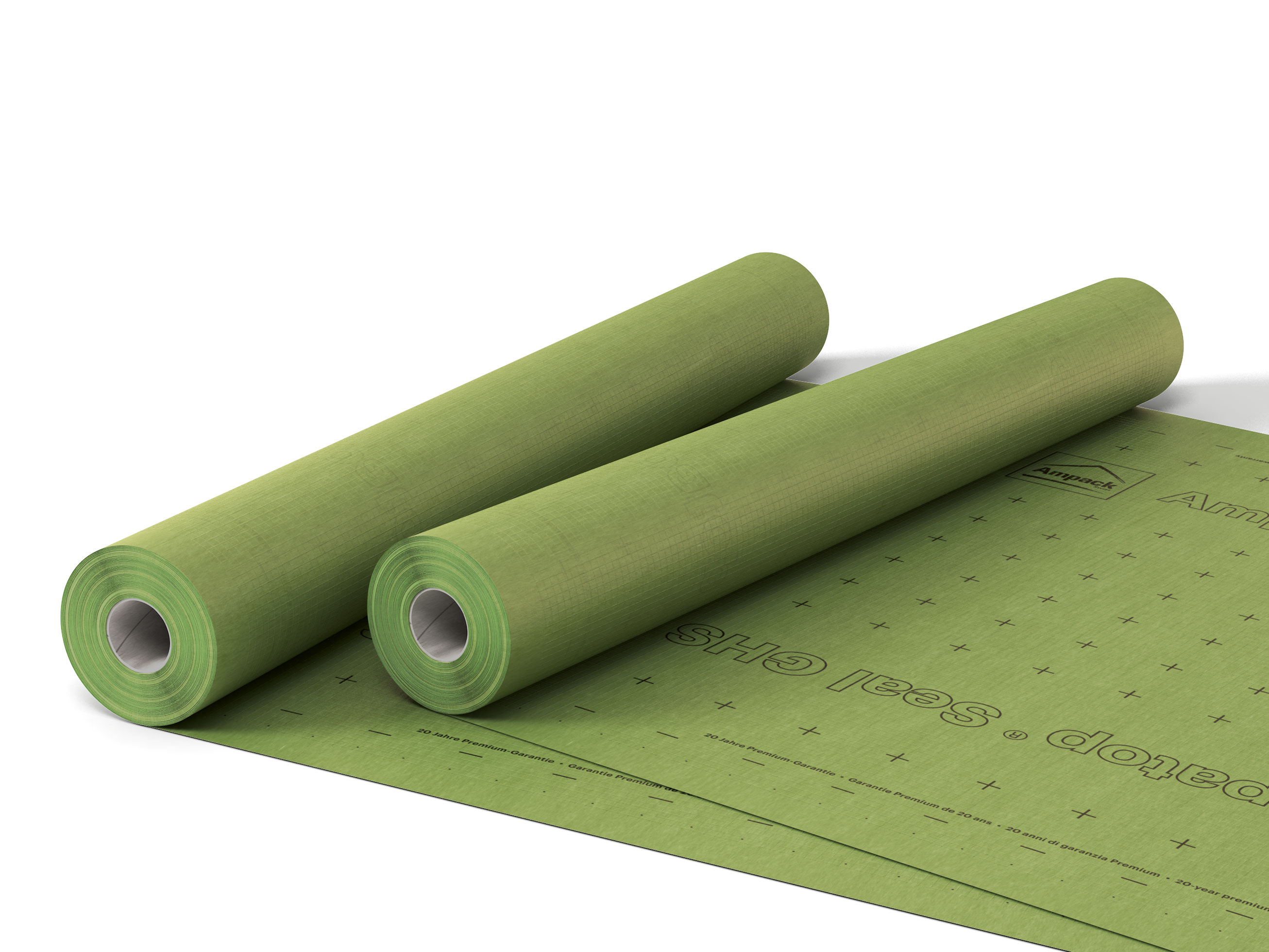

Product photos

|

|

Ampatop Seal: product photo GHS | Ampatop Seal: product photo GHS, weldable roof membrane |

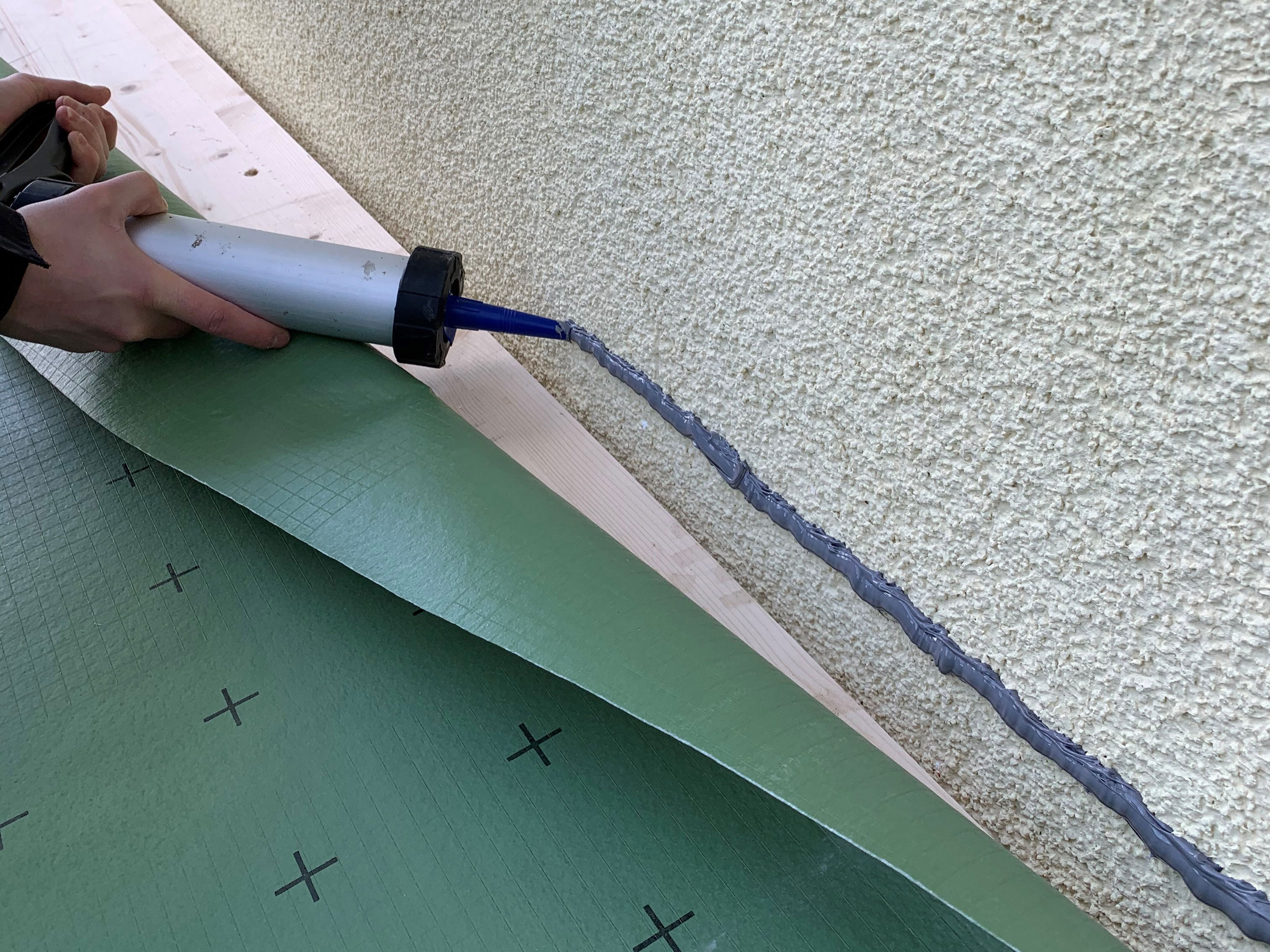

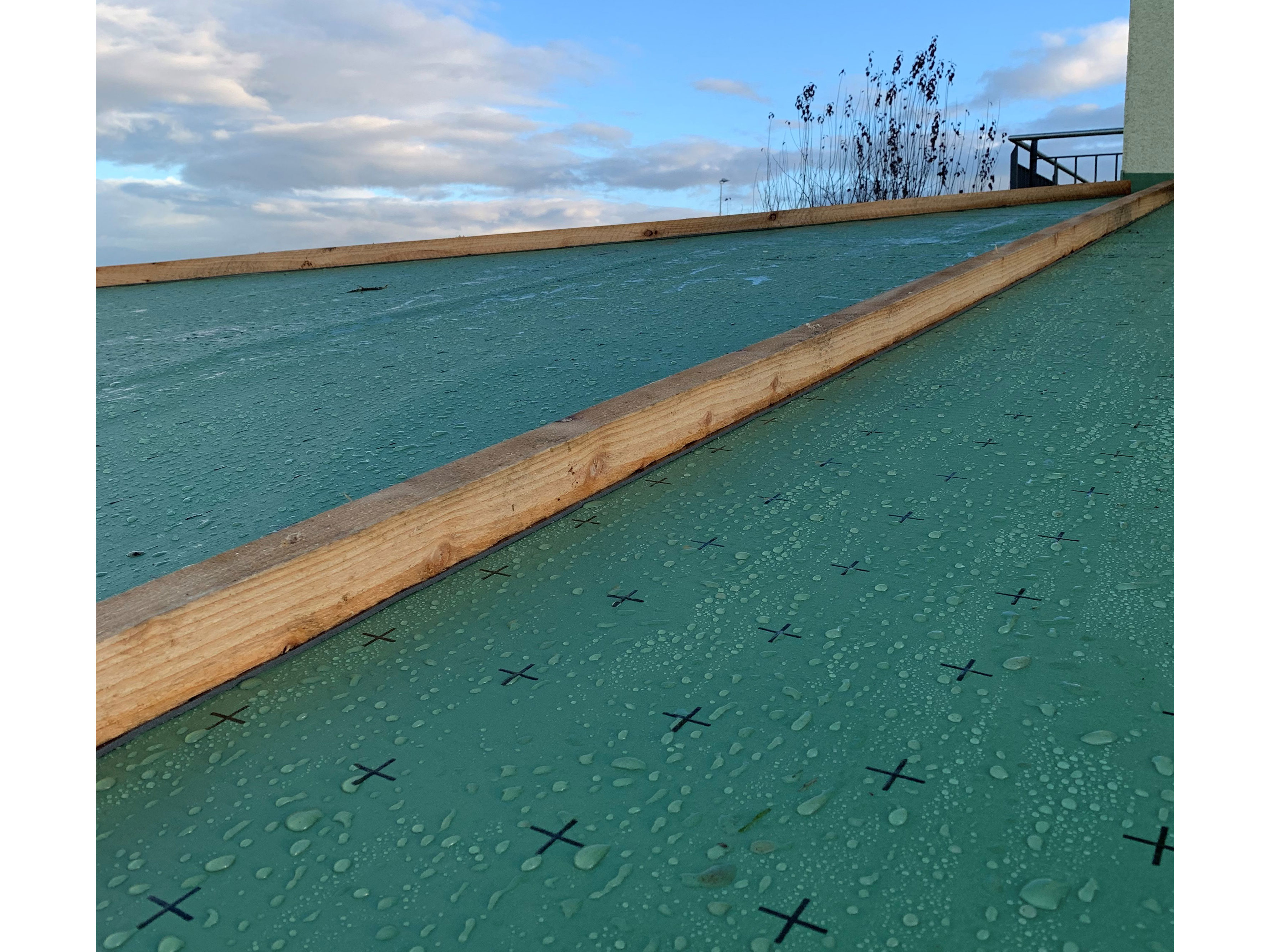

Application photos

|

|

Application photo: Ampatop Seal GHS | Application photo: Ampatop Seal GHS, weldable roof membrane |

|

|

Application photo: Ampatop Seal GHS | Application photo: Ampatop Seal GHS, weldable roof membrane |

|

|

Application photo: Ampatop Seal GHS | Application photo: Ampatop Seal GHS, weldable roof membrane |

|

|

Application photo: Ampatop Seal GHS | Application photo: Ampatop Seal GHS, weldable roof membrane |